【 New Energy News】Future Battery Industry Aims at All Solid State Batteries

In the past 10 years, the energy density of liquid lithium-ion batteries has increased by 2-3 times and is currently approaching the theoretical upper limit. All solid state batteries use solid electrolytes instead of traditional lithium-ion battery electrolytes and separators, which are safer, have higher energy density, and stronger cycling performance, and have become the main research and development direction for the next generation of power batteries recognized in the industry.

Recently, the 2023 World Power Battery Conference with the theme of "Green New Power, World New Energy" opened in Yibin, Sichuan Province. This conference invited multiple renowned academicians and experts to attend, bringing together more than 300 important guests from industry leaders and multinational corporations. The conference focused on hot topics such as next-generation power batteries and all solid state batteries, and deeply analyzed the trend and development prospects of the power battery industry.

In his opening speech, Wan Gang, Chairman of the China Association for Science and Technology, pointed out the need to increase efforts in the research and development of next-generation power battery technology, scientifically judge the technological route of next-generation power batteries, attach importance to basic research and technological development of new materials and new system batteries represented by all solid state batteries, systematically solve technical problems in key materials and system integration of new system batteries, promote industrial application and demonstration operation, Simultaneously conducting market and technology evaluations to provide leading experience for the scale and industrialization development of the next generation of power batteries.

So, what is the next generation power battery? Why promote the research and development of next-generation power batteries?

The energy density of power batteries is approaching the "ceiling"

The battery material directly determines the energy density, safety, and cost of power batteries, and energy density is a key indicator of power batteries. At present, China has formed a development path for power batteries mainly consisting of ternary lithium-ion batteries and lithium iron phosphate batteries. The energy density of ternary lithium-ion batteries in China can exceed 300 watt hours/kg, and the energy density of lithium iron phosphate batteries can exceed 200 watt hours/kg, both reaching the world's advanced level.

Power batteries have the advantages of high energy, high battery voltage, wide operating temperature range, and long storage life, and have been widely used in small electrical appliances. Currently, power batteries have partially replaced traditional batteries in products such as mobile phones, portable computers, cameras, and more. Large capacity lithium-ion batteries have also been tested in electric vehicles, becoming one of the main power sources for electric vehicles and will be applied in aerospace, energy storage and other fields.

However, with the continuous innovation of power battery technology, traditional materials are difficult to meet the needs of battery cost reduction, efficiency improvement, and energy density improvement. For example, the current lithium iron phosphate battery has an energy density close to the ceiling, and its specific energy is still relatively low, and its low-temperature performance needs to be improved. At the same time, the trend of fragmentation in the power battery market is becoming increasingly evident, and the differentiation level of battery products is further improving. Innovation in power battery technology routes can also better meet the diverse application needs of scenarios. Therefore, the next generation of power batteries has emerged.

"Compared with lithium-ion batteries, the next generation of power batteries can reduce material costs by 30-40%." said Sun Quannan, Vice President of LG New Energy and President of the Next Generation Battery Research Institute. LG New Energy is continuously investing in the research and development of lithium sulfur batteries and lithium metal batteries based on liquid electrolytes to overcome the current energy density limitations of lithium-ion batteries.

All solid state batteries are the next generation of power batteries closest to us

Experts have stated that in the past 10 years, the energy density of liquid lithium-ion batteries has increased by 2-3 times and is currently approaching the theoretical upper limit. All solid state batteries use solid electrolytes instead of traditional lithium-ion battery electrolytes and separators, which are safer, have higher energy density, and stronger cycling performance, and have become the main research and development direction for the next generation of power batteries recognized in the industry.

All solid-state batteries are claimed to be the "ultimate form" of lithium-ion batteries, because true solid-state batteries have "too many advantages" compared to current liquid or lithium-ion batteries.

Firstly, all solid state batteries use solid electrolytes instead of traditional liquid electrolytes, which have high ion conductivity and can provide higher battery energy density.

Secondly, compared to traditional liquid lithium-ion batteries, the most prominent advantage of all solid state batteries is their safety. The electrolyte in traditional liquid lithium-ion batteries is flammable and volatile. Once leakage or short circuit occurs, it may lead to fire or explosion. Solid electrolytes are solid materials with high thermal stability and flame resistance, which can effectively reduce the risk of battery leakage and thermal runaway.

Again, all solid-state batteries also have a longer lifespan. Because the stability of solid electrolytes can slow down the deactivation and degradation process of batteries, extend the service life of batteries, prevent the growth of electrode dendrites in metallic lithium, reduce the volume expansion and damage of electrodes, and improve the cycling stability of batteries.

Finally, a significant factor in making all solid state batteries the main research and development direction for the next generation of power batteries is the low cost of replacement. The technological innovation of lithium sulfur batteries, lithium air batteries, etc. requires the replacement of the entire battery structure framework, which is difficult to achieve.

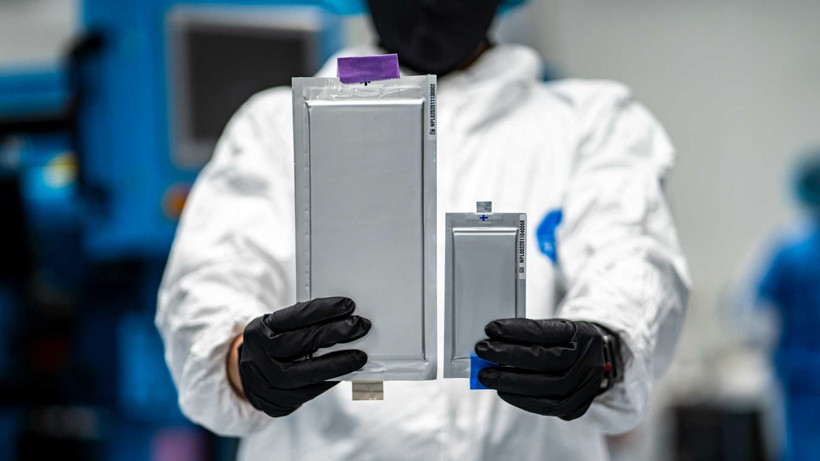

The technological innovation of all solid state batteries mainly lies in the innovation of electrolytes. The positive and negative electrodes of the battery can continue to use current materials, and the difficulty of implementation is relatively small. The consensus among the scientific and industrial communities is that solid-state batteries are the next generation of power batteries closest to us.

"We found that the papers related to all solid state battery technology published in the world's top journals are growing exponentially, which can be said to be on the eve of the commercialization of this technology." Ouyang Minggao, an academician of the CAS Member and a professor of Tsinghua University, said that now there are countless relevant industry personnel in the world who have invested in the research and development of all solid state batteries. With the continuous improvement and innovation of battery technology, the exploration efficiency of new materials continues to improve, Effectively shortening the research and development cycle, all solid-state batteries are moving from concept to reality.

The development of all solid state batteries faces challenges but has broad prospects

Of course, the next generation of power batteries still has a long way to go before practical applications. Sun Xueliang, a foreign academician of the Chinese Academy of Engineering, a member of the Royal Canadian Academy of Sciences, and a member of the Canadian National Academy of Engineering, stated that the physical, chemical, and mechanical properties of the positive electrode, electrolyte, and negative electrode of all solid state batteries still need to be improved, and the compatibility and interface stability between materials still need to be improved. The overall safety management strategy and engineering preparation technology of batteries are not yet mature, which are all difficulties that need to be overcome.

Compared to structural innovation, the improvement in battery materials is slower, which is the main challenge that current all solid state batteries urgently need to solve.

For example, globally, Japanese and Korean companies started earlier and often "bet" on the route of sulfide all solid state batteries. However, the air stability of sulfide electrolytes is poor. When exposed to air, toxic gases are produced, accompanied by the destruction of electrolyte structure and degradation of electrochemical performance. Therefore, the synthesis, storage, transportation, and post-treatment processes of sulfide electrolytes heavily rely on inert gases or drying rooms. In addition, Europe and America have turned their attention to polymer solid-state batteries. However, polymer electrolytes have low ionic conductivity at room temperature, which requires the charging of polymer all solid state batteries to be completed in high-temperature environments, greatly limiting their commercial applications.

Most enterprises in our country are taking the route of oxide solid-state batteries. Most oxide electrolytes have a wide electrochemical stability "window" and better oxidation stability, but in order to ensure good interface contact between rigid oxide electrolytes and cathode materials, high-temperature sintering is often required, otherwise it will lead to serious interface chemical side reactions. In addition, some oxide electrolytes also have lithium dendrite growth issues.

Although there are still many technical challenges to be solved for the next generation of power batteries, and industrialization and large-scale application still face certain challenges, relevant experts are still optimistic about the development prospects of the next generation of power batteries. They unanimously believe that further development of all solid state batteries is a necessary strategy to achieve the goals of high safety, long cycle life, and high energy density for electric vehicle batteries.

中文

中文

English

English